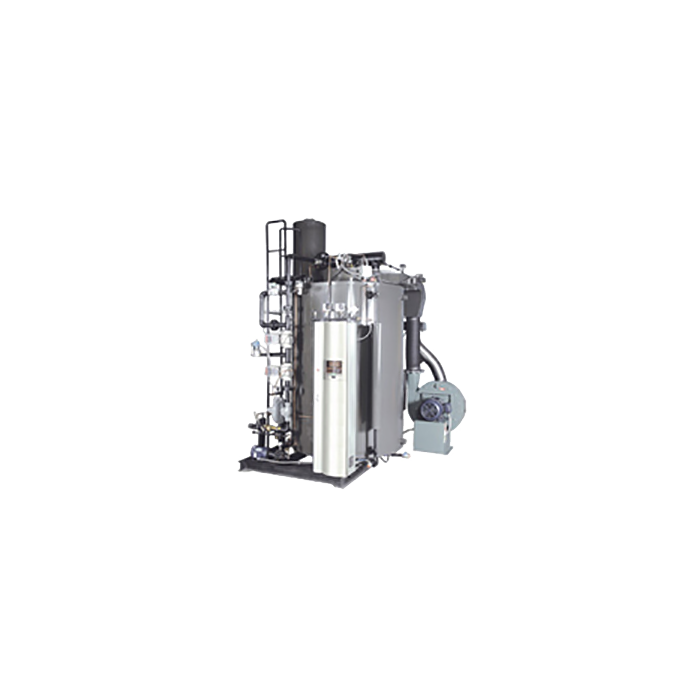

EX Series Steam Boilers

The EX Gas/Oil Series High Pressure Steam Boiler is the most versatile industrial steam boiler in the world. The EX design minimizes carryover and produces dry 99+% saturated steam in 5 minutes or less from a cold start. Faster start-up means less fuel used, greater savings, and more responsible use of precious natural resources.

EX Series Model Design – Miura is known world-wide for our commitment to protecting the environment and our innovative and efficient boiler designs. Our EX Gas/Oil Series High Pressure Steam Boiler is the most versatile industrial steam boiler in the world. The EX design minimizes carryover and produces dry 99+% saturated steam in 5 minutes or less from a cold start. Faster start-up means less fuel used, greater savings, and more responsible use of precious natural resources.

- EX-100 SGO – 100 HP – 3,348,000 BTU/HR

- EX-150 SGO – 150 HP – 5,022,000 BTU/HR

- EX-200 SGO – 200 HP – 6,695,000 BTU/HR

- EX-250 SGO – 250 HP – 8,369,000 BTU/HR

- EXN-300 SGO – 300 HP – 10,050,000 BTU/HR

- EX-300 SGO – 300 BHP – 10,040,000 BTU/HR

Click here for Detailed Product Specifications

Additional Benefits

- Dual fuel fired Natural Gas, Propane or #2 Fuel Oil

- High pressure options available (300 MAWP, 250 MAWP or 170 MAWP)

- Hot water boilers are available depending on models (refer to the catalog for the hot water boilers for details)

- NOx rating is available as low as 30ppm, depending on model

EX Series Model Design

The MIURA EX Series design consists of rows of vertical tubes sandwiched between two rectangular headers. Both headers are encased in a castable refractory with only the tubes exposed to flame and/or combustion gases. The upper header is attached to the lower header only by the tubes. As the tubes expand and contract, the headers float up and down accordingly.

This ’floating header’ concept greatly reduces stress and allows for the use of cold feedwater without the fear of significant thermal shock. The ’leaky tube’ problems associated with firetube and bent watertube designs have been eliminated.

Ultra Compact Design Saves Space and Costs

Miura’s EX Series boilers occupy 33% less floor space than typical firetubes, and do not require tube pull space. Compact design means much smaller radiation losses and larger fuel savings.

Full Steam Output In Less Than 5 Minutes

Floating headers mean fast start-up. MIURA boilers produce fast steam in less than 5 minutes from a cold start-up. Standard firetubes require 1 to 1.5 hour start-up times. Miura’s unique design yields significant time and fuel savings.

Dry Steam

The MIURA EX design minimizes carryover and produces dry 99+% saturated steam through a 3-stage process: •Initial separation in the tubes

•Second separation in the upper header and baffle plate

•Final separation in the cyclone separator

Early Warning Scale Monitor

Scale is a problem all boilers have to deal with. Scale forms when boiler feedwater is not properly treated. Advanced scale formation acts as an insulator; only an eggshell thickness of scale results in a 10% efficiency loss, higher fuel bills and possible damage to the boiler system.

As standard equipment, all Miura EX models are equipped with a thermocouple attached directly to a tube. Should scale begin to form, the Miura boiler will alert the operator – allowing the operator to trace and repair the source of the water hardness. The scale can be removed to restore the boiler to its original efficiencies – saving tens of thousands of dollars in wasted fuel and repair bills.

Unbeatable In-Service Efficiencies

Miura’s computer-aided design results in optimal heating surface transfer with minimal water content for fuel-to-steam efficiencies of 85%. Typical firetube designs can deliver up to 83% fuel-to-steam efficiencies. However, in actual use, MIURA averages 10 to 40% fuel savings over standard firetube designs. How does a 2% difference in fuel-to-steam efficiencies translate into a 10 to 40% ACTUAL FUEL SAVINGS? Contact your local Miura representative for details.

| Hide Prices | Yes |

|---|---|

| Featured | No |

| Show Add To Cart | No |

Contact Us to Request a Quote

Connect with a real person who will go out of their way to help!

Fill out the form below or call us at: 877-377-0011